Setting Shop in India

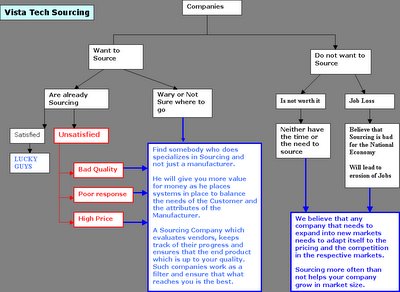

Every company which has had an ambition to grow out of its strong markets has , at some point or the other contemplated manufacturing its components in the lower cost markets.

More often than not it has been a stop gap arrangemnet or a trial run which probably tends to lose its sheen.

How have the companies which have sourced and succeeded gone about it. We have studied many cases and our conclusions are predictably surprising.

A) EXPERIENCE : Most companies which began by component sourcing and found a good source have gone ahead and set up shop in the region from where they found the source . The quite obvious reason should be that they had suceeded and it is easy to replicate success especially if it is your own and not your competitors.

B) BREAK EVEN : The typical break even periods for an investement if the company can take about 70% of its new production for captive use in the world markets ( and not the market of the source region) , is 1-2 years. This is a calculation considering only the investment made and the profit generated by the new plant. When you consider that the product taken back to the world market is almost at a 30 % ( very conservative) cost advantage , the break even is further reduced.

C) MACHINING: The favorite method of all the companies is to start with a component involving machining. The prime reason being that lower labor costs ( which is what primarily makes the markets low cost) give more commercial advantage on machined components.

D) END PROCESS CONTRACTING : Some of the companies have a very intresting strategy. They set up a basic unit which only does the last leg of the product line ( like assembling, end welding, final machining etc) . These are typically companies which are attempting to reduce the load on their main factories and while doing so also gain the advantage of reducing costs and attaining a global footprint.

We have been presenting these ideas,along with project costs and financial analysis , to a few companies in the US/UK and Europe and the responses have been quite encouraging. Once the uncertainity or fears of the conditions of a new location are removed, clarity on the substantial and hetherto unkown cost advantage becomes visible.

The remorseless pressure of the markets cost dynamics is too compelling a factor for companies to ignore.